Deformed Steel Bar / TMT Bar

Thermo mechanically treated steel, known as TMT steel, can be described as a new-generation-high-strength steel having superior properties such as weld-ability, strength, ductility and bend-ability meeting highest quality standards of international level. RE-BARS is manufactured from superior quality billets manufactured in the same plant according to the requirement of the customers. RE-BARS of FE-500D/FE 550 grade for sizes as per IS 1786-2008 / BS4449 standards ranging between 8mm to 40mm. The standard length of the bar is 12mtrs and or customized length can be available against specific request.

TMT bars up to 12 mm are available in coil form as well as de-coiled and straightened.

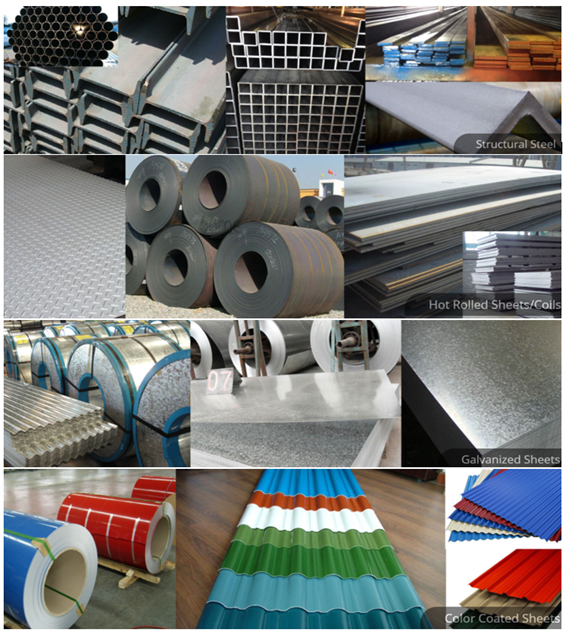

Structural Steel

MS Angles

Structural or Long Products with L Section. It is widely used in fabrication and is generally available in various sizes from 25 mm to 200 mm.

MS Beams

We offer the finest quality MS Beams, Joists, all sizes and grades are available.

MS Plates

We offer complete range of Structural Steel Plates / High Tensile Steel Plates , Boiler Quality (BQ Plates) / Pressure Vessel Quality Steel Plates , Ship Building Steel Plates.

Chequered plates

It is with distinct design and highly slip resistant. Length can be customized.

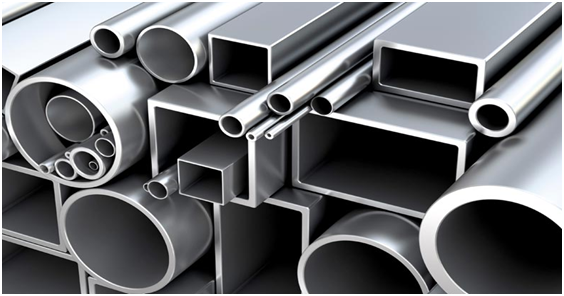

MS PIPES / TUBES

The hollow sections are available in round, square and rectangular cross sections with a standard length of 20’/ 6 metres. Mild Steel Pipes / Tubes are used in pre-engineering buildings, scaffolding etc.

GP Sheets / Coils

It is Cold Rolled Sheets/Strips coated with zinc metal. Process is known as Galvanising. Used in roofing, paneling etc. GP sheets are normally produced by Hot Deep Galvanising of CR Sheets/Strips in liquid zinc bath. GC sheets are obtained upon corrugating of GP sheets in corrugating machine. Colour coated sheets are also available.

Galvalume Sheets / Coils

It is a superior product renowned for its excellent corrosion resistance and heat reflectivity. The alloy coated product nominally contains 55% aluminum, 43.5% zinc and 1.5% silicon by weight. Applied by the traditional hot-dipping process, the product is ideal for applications requiring superior corrosion resistance and heat reflectivity, typically required for building construction, appliances, and IN several non-exposed automotive components. The product’s shiny spangled appearance is attractive and can be used without painting. Colour coated sheets are also available.

GI Pipes

Galvanised Iron (GI) Pipes are manufactured using mild steel strips of Low Carbon Steel Coils. The GI Pipes are generally used for distribution of treated or raw water in rural or urban areas or construction purpose. These pipes are cheaper, light weight and easy to handle.

Stainless steel

Stainless steel is a generic term for a family of corrosion resistant alloy steels containing 10.5% or more chromium. All stainless steels have a high resistance to corrosion. The available products are Sheets, Coils, Pipes, Rods, Angles, Channel, Flat etc.,

MS & GI Binding Wire

Binding Wire is used for the purpose of tying applications in the field of construction. It is used extensively in the construction sector for tying the re-bars at the joints so as to keep the structure intact.

MS & GI Binding Wire is available in both 18 and 20 SWG

GI Wire - Galvanized wire - Galvanisation is an industrial process by which a coating of zinc is applied to sheets of steel or iron to act as a protective layer against corrosion, most commonly in the form of rusting.

Cement

Ordinary Portland Cement

It commonly used cement for a wide range of applications. These applications cover ordinary, standard, high strength concretes, masonry and plastering works, precast concrete products for e.g., blocks, pipes etc., and specialized works such as precast and pre-stressed concrete.

Portland PozzolanA Cement

Portland cement clinker is mixed with pozzolanic materials, the result is PPC. PPC produces less heat of hydration and offers greater resistance to the aggressive waters attacks than ordinary Portland cement (53 and 43-grade cement). Moreover, it reduces the leaching of calcium hydroxide liberated during the setting and hydration of cement. It is particularly useful in marine and hydraulic construction and other mass concrete structures.

Sulphate Resistant Cement (SRC)

This cement is used in marine conditions where soil or water contains excess sulphates.

All the above cements are available in both Loose and Bags

Ready Mix Concrete

Ready Mix Concrete is a ready-to-use material which is a mixture of Cement, Sand, Aggregate and Water. RMC is a type of Concrete which is mixed in a batching plant according to the specification of the customer and delivered to the site by the use of transit mixer as it is away from the construction site.

Various grades from M5 to M60 we shall supply as per end user design mix.

Autoclaved Aerated Concrete (AAC) Blocks

AAC Blocks which is a perfect solution for all kind of building structures being Schools, Hospitals, Corporates, Hotels, Individual Housing, and Apartments. Our green building products are eco-friendly and cost-effective and thus save your Project – Time, Money & Resources

We offer sizes from 4" to 9"

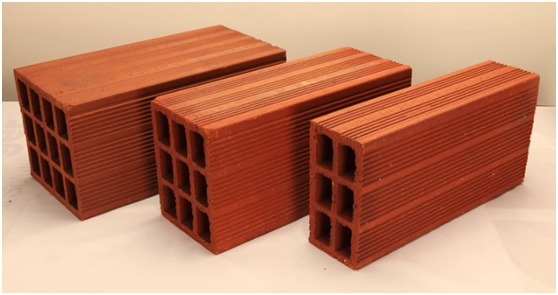

Porotherm Blocks

Porotherm is a clay block walling system – ideal for the construction market. It is virtually dry, safe and simple to use, immensely strong, efficient for stock-holding and storage and environmentally friendly.

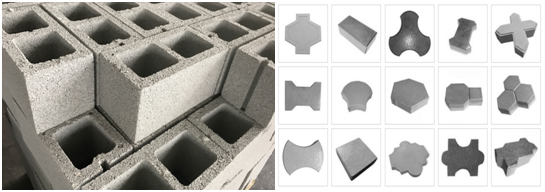

Solid Blocks

Solid concrete blocks of size 400 mm × 200 mm × 150 mm are commonly manufactured. To reduce the weight of the block no fine concretes are preferred. No fine concrete is the concrete in which fine aggregate is not used, but round aggregates of size less than 12 mm are used. IS:2185 (part I) 1983 covers the requirement, for such blocks. Their density should be as low as possible, so that handling is not difficult. They should have sharp edges which are at right angles to each other.The blocks should satisfy the strength requirement of 4 N/mm2.

Concrete Blocks

Both solid and hollow blocks can be used for the construction of load bearing as well as partitionwalls. They are ideally suited for the construction of compound walls. The blocks should satisfy the strength requirement of 4 N/mm2.

Solid Concrete Blocks: Solid concrete blocks of size 400 mm × 200 mm × 150 mm are commonly manufactured. To reduce the weight of the block no fine concretes are preferred. No fine concrete is the concrete in which fine aggregate is not used, but round aggregates of size less than 12 mm are used. IS:2185 (part I) 1983 covers the requirement, for such blocks.

Their density should be as low as possible, so that handling is not difficult. They should have sharp edges which are at right angles to each other.

Hollow Concrete Blocks: To reduce the weight of concrete blocks, they may be made hollow as shown. Hollow blocks of sizes 400 mm × 200 mm × 190 mm (nominal size 400 × 200 × 200 mm) and also of sizes 400 mm × 300 mm × 190 mm (nominal size 400 × 300 × 200 mm) are manufactured. IS:2185 (part I) 1983 covers the specifications for these blocks.

These block need richer mixes. Fine aggregates up to 60% and coarse aggregates up to 40% are used.

Paver Concrete Blocks: is a cost effective, durable alternate method of paving as compared to rigid concrete paving or flexible asphalt paving.The applications are varied such as in ports, container terminals, industrial hard standing areas,bus / truck terminal, slow speed roads, residential / commercial drive ways, petrol filling stations, aircraft taxiways etc. Ease to access to underground services and the fact that the blocks can be reused to restore the pavement to its original profile.

Fly Ash Bricks

Fly Ash Brick is a product of basic cement clinker materials i.e. FLYASH, STONE DUST/SAND, LIME, GYPSUM and BONDING AGENT. The mix is so ideally worked out to produce bricks of higher strength with consistency as well as uniformity.. The manufacturing process is fully automatic with state of art technology. Higher compressive strength. It lower water absorption.

Red Bricks

Bricks are essential raw material required in every construction but which type of brick should be used in specific type of construction is important to know. Bricks vary in type, size and shape that are used in masonry purpose.

Actual bricks that are used for construction must be properly dried and treated for better durability. Bricks are said to be completely burnt when they make hard sound on being clasped together. Good bricks are characteristics with good & uniform shape, correct rectangular shape and hard edges.

Rock Boulders

Available in a variety of sizes from 50Kgs to 1500Kgs, and suitable for use in gabion baskets, anti-scouring of drainage channels, rip rap, sea walls, stone walls, landscaping and shore protection.

Granular Sub Base(GSB)

Well graded unbound material, usually crushed stone, crushed slag, crushed concrete or another inert hard material. The most common unbound granular sub base material used to form a path base is Type 1.

M-Sand

Manufactured Sand (M Sand) is an excellent replacement for natural river sand. It is crushed fine aggregate produced from a source material and designed for use with concrete, plastering, brick works in construction. Production generally involves crushing, screening and possibly washing.

It does not have the presence of impurities such as clay, dust and silt coatings, increase water requirement as in the case of river sand which impair bond between cement paste and aggregate. Thus, increased quality and durability of concrete.M-Sand are more eco-friendly than river sand.

River Sand

River sand is procured from river streams & banks. This type of sand has rounded grains generally in white-grey colour. River sand has many uses in the construction purpose must be clean, free from waste stones & impurities. It is important to know what type of sand is beneficial for construction purpose as sand is also classified into three different forms that make it suitable for specific type of construction.

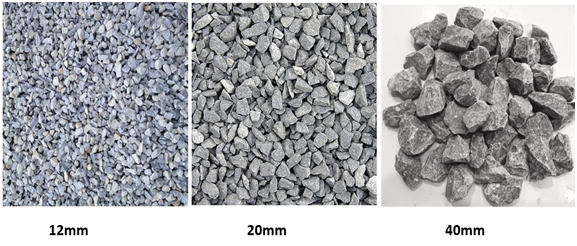

Aggregates (Blue Metals)

Construction aggregate, or simply “aggregate“, is a broad category of coarse particulate material used in construction, including and, gravel, crushed stone, slag, recycled concrete & geosynthetic aggregates.

Aggregates are the most mined materials in the world. Aggregates are a component of composite materials such as concrete & asphalt concrete; the aggregate serves as reinforcement to add strength to the overall composite material. Due to the relatively high hydraulic conductivity value as compared to most soils, aggregates are widely used in drainage applications such as foundation and French drains, septic drain fields, retaining wall drains & Road side edge drains.

Construction aggregate, or simply “aggregate“, is a broad category of coarse particulate material used in construction, including and, gravel, crushed stone, slag, recycled concrete & geosynthetic aggregates. Aggregates are the most mined materials in the world. Aggregates are a component of composite materials such as concrete & asphalt concrete; the aggregate serves as reinforcement to add strength to the overall composite material. Due to the relatively high hydraulic conductivity value as compared to most soils, aggregates are widely used in drainage applications such as foundation and French drains, septic drain fields, retaining wall drains & Road side edge drains.

Sizes available: 6mm, 12mm, 20mm, 40mm, etc.,

Gypsum Plaster or Plaster of Paris

Gypsum plaster, or plaster of Paris, is produced by heating gypsum to about 300 °F. When the dry plaster powder is mixed with water, it re-forms into gypsum.

Plaster of Paris is a building material that is used as a protective coating on walls and ceilings.

Cinder (Light Weight)

We haveCinder (Light weight), 20mm Cinder, 40mm Cinder. It can be used for Toilet deck filling, Roof garden filling, Horse race track, Running Track. It has so many cavities that its low density of 0.641g/cm^3 allows it to float in water. Cinder is typically brown, black, or red depending on its chemical content.